ONEWOOD HRT Technology utilises fibers from fast growing plantation trees that are ready to harvest within 5 - 10 years.

Fibers from fast growing plantation trees undergo an upcycling process.

To create a hardwood material that has the quality and size that an 80 - 100 year old tropical rainforest tree can provide - ONEWOOD Homogeneous Reconstituted Timber

With the world’s high consumption of wood volume, the natural forests are unable to replenish fast enough to supply its demands. ONEWOOD HRT Technology upcycles wood fiber from fast growing plantation that are ready for harvest within 5 - 10 years and manufactured to hardwood material with premium size and length with high yield that only an 80 – 100-year-old tropical tree can provide.

Being a sustainable alternative to natural timber, ONEWOOD timber is engineered with value-added properties such as fire resistance, termite resistance, water resistance and exceptional dimensional stability. ONEWOOD is a solution to many common timber issues such as rotting, warping, twisting and termite infestation. The product does not only perform better than natural timber, but it also looks and feels exactly like natural timber.

Natural timber harvested from these fast-growing plantations have limited usability and durability for timber products used on the built environment. Yet with the Homogeneous Reconstituted Timber technology, we are able to create a timber product that has much higher usability and durability, with the very same raw materials. Using ONEWOOD in the built environment reduces the pressure on the environment as its product life is significantly more durable as compared to natural timber products and / or other timber alternatives.

ONEWOOD Technology that utilizes much higher yield of raw materials as compared to logging natural hardwood in natural forests.

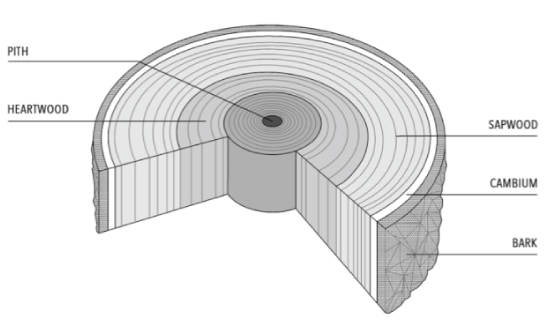

In a typical tropical hardwood such as teak, rosewood and mahogany, only the heartwood portion can be used as hardwood from these trees which leads to low hardwood yield after harvest, while other areas are considered wastage and consumed in the form of biomass energy. Irregular shape the logs and wood defects within the heartwood such as large cracks and bore holes can further contribute to low hardwood yield.

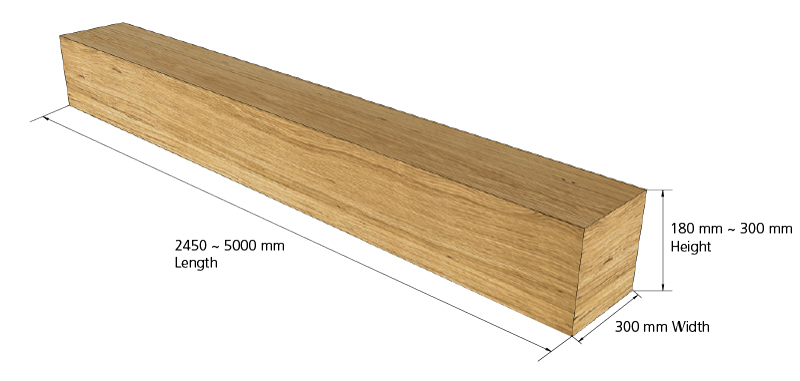

A standard block of ONEWOOD Timber

A standard block of ONEWOOD TimberONEWOOD technology is able to utilize twice as much wood fiber as compared to logging natural hardwood. ONEWOOD blocks are manufactured to significantly reduce common defects found in natural hardwood such as bore holes or empty heart wood. The product yield of ONEWOOD timber blocks raised up to 90 – 95% efficiency.

Beyond sourcing for eco-friendly raw materials, ONEWOOD also adopts environmentaly friendly production processes. It has been awarded the Singapore Green Label Scheme and Singapore Green Building Product certification.

There are many ways where ONEWOOD can excel and present itself as a sustainable product. Each aspect in sustainability - the product performs in terms of durability and reusability enhances each other to create positive impacts to the environment. With ONEWOOD as the future in timber alternatives, we can conserve our beautiful natural trees in the forest to flourish and still able to meet demands for a good, stable timber material.